Debunking a Soldering Myth 2

2 Minute Read

There are many myths about heating pieces during soldering that can cause innumerable problems during relatively simple soldering operations. In this occasional column, I will address the top soldering myths and the essential criteria to be used in evaluating soldering techniques.

Soldering Myth You must heat the entire piece while soldering

Nearly every book and article about soldering concepts contains this myth. Even The Theory & Practice of Goldsmithing by Prof. Dr. Erhard Brepohl includes this myth: "When using jeweler's solder, it is always necessary to heat the entire piece."

His book is my favorite, and by far the most useful jeweler's reference that exists. I assign it to all our apprentices because concepts are explained in detail, and scientific data is provided to prove and illustrate all concepts. The only exception to this is the aforementioned statement. There is no data to support that the statement is accurate or even a description of what negative effects could be expected if the advice was ignored. This prompted me to test this theory for myself.

For years I tested and retested on fine and sterling silver as well as 14k to 22k gold, and on pieces ranging from very small earrings, pendants, rings, and pins up to large, thick cuff bracelets. What I discovered is that it is not necessary to heat the whole piece to get solder to flow successfully on typically sized jewelry pieces. The only exceptions I have found are very large flat pieces that may expand and contract out of alignment if heated in just one spot and are best fully supported if this method is used. (I use a screen set up on a tripod.)

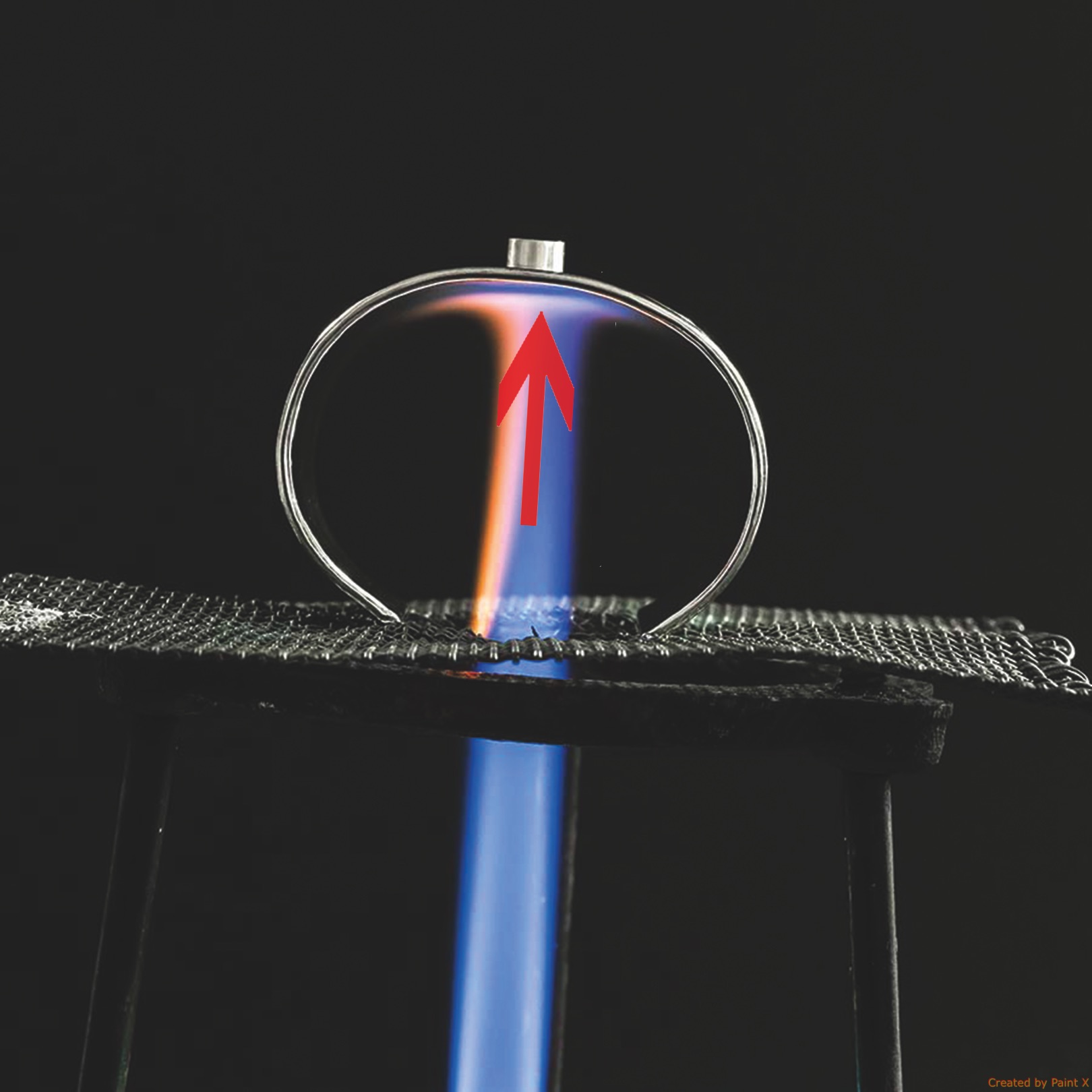

For solder to flow successfully, the entire seam you are intending to fill must get hot. But that doesn't mean the entire piece needs to be heated. This is a critical difference and changes everything about what method to use while heating. Solder will flow to the hottest area of the piece first. You can't get your seam hot enough to solder while you are going around and around the whole piece; too much of the heat will dissipate. Instead, keep your torch positioned near the seam you are trying to fill.

You'll be amazed at how quickly and beautifully the solder flows when you aim the heat at the place you are soldering rather than circling around it. My pieces suffered no ill effects from not heating the whole piece, such as solder seam breakage or failure. In addition, this method cuts down on the formation of oxidation, an important benefit for quick and clean solder flow.

Editor's Note

This article is excerpted from "Soldering Demystified," a paper presented at the 2015 Santa Fe Symposium on Jewelry Manufacturing Technology. To order a copy of the paper, visit santafesymposium.org.

Jeanette K. Caines is the director of Jewelry Arts Inc. (jewelryarts.com) in New York City, and the author of Soldering Demystified (available on Amazon).

Ganoksin Staff Note: Finding The Best Soldering Tools & Supplies

By following the techniques illustrated above, you'll make vast improvements in your soldering. You can also take your work to the next level by investing in some better tools. We have current, expert reviews of all the best soldering tools, supplies and equipment in our Buying Guide section:

Best Soldering Station Reviews: read more

Best Third Hand Tool Reviews: read more

Best Jewelers Torch Reviews: read more

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.